Innovation in the research and development unit of Salargaster Company

In the research and development unit of Salargaster Company, innovation and use of the latest technological achievements in the world in two categories of testing, design and development mechanisms New products are crystallizing.

In the implementation category, test mechanisms using the power of internal forces to design specific test systems for production parts. The view of finding the problem form is done according to the needs of the experts of the part in terms of quantitative parameters necessary for testing. Then by researching and finding solutions including automation systems and PLC. HMI and special sensors suitable for measuring quantitative parameters will be implemented.

By reviewing the testers used in the production lines and laboratory of Salargaster Company, examples of such testers can be seen, which include artificial intelligence equipment. – Image processing – fiber optics – laser -.. According to the experience gained in this company in the field of artificial vision, we will soon see the equipping of production stations with VISUAL INSPECTION systems, thus minimizing operator error and infallibility.

We also design and build automatic units to optimize the use of manpower in production and reduce human error as much as possible. .

In the category of design and development of new products in the research and development unit of Salargaster Company, a part of the car alarm system is designed and in the mass production stage. We are among the other new components that are in their research stage is the very important component BCM: BODY CONTROL MODULE , which is for the integration of vehicle electronic units and network communication with the ECU unit.

The BCM unit is one of the achievements of the world automotive technology, which creates many optimizations, including reducing the cost of the wire tree and smartening the car components. he does. As we see the use of this part in the cars of the day. Salargaster’s R & amp; D unit is researching world-renowned brands to use this technology to take steps to improve and enhance the domestic automotive industry.

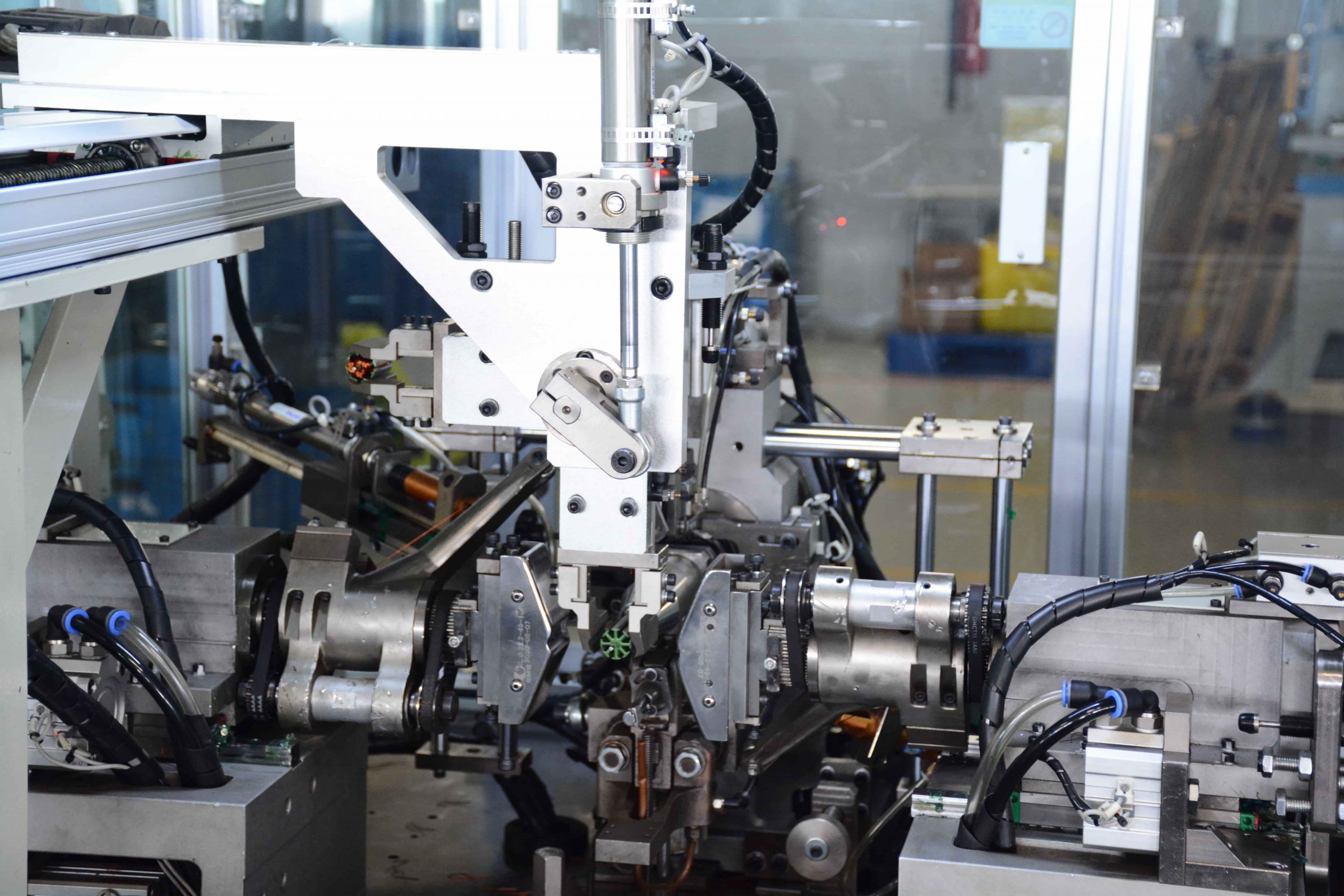

Infallible processes

Using innovation, using new methods and buying the latest technology in the world, production processes are designed and built in such a way that it is not possible to produce a defective product.

In workstations where it is not possible to be infallible, automatic control methods are used so that defective products are not sent to the next stations.

Progressive templates

Salargostar Molding and Pressing Unit, while using valid domestic presses such as Khavar Press, has used foreign brands such as Yadun for presses of 250 tons and above, as well as its High Speed presses.

Also, all molds are made with special imported alloys and in a progressive way, so that during the three work shifts, the operators refer only to charge the sheet and collect the produced parts.

Fully automatic lines

In order to reduce manpower errors; Increasing productivity and technology localization All new product lines have been designed and built with the approach of maximizing automation, and these lines are working around the clock.

To build machines, while using the latest engineering knowledge in the world, the required hardware has been purchased and used from reputable brands.